Linear Slides by Deltron: An Overview

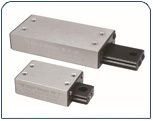

Linear slides are only one of the many linear motion products manufactured by Deltron Precision, but when engineers and designers need just the right linear slide for an application, they look to Del-Tron Precision. (Click here for our Linear Slides, Ball Slides, and Crossed Roller Slides page.) Over the last 30 years, there have been great strides in the manufacturing and quality of linear slides. Their light weight, smaller footprint, increased load-carrying capabilities and accuracy make them the perfect design solution for a wide range of applications.

Today's linear slides are packed with power

• Low friction straight-line design reduces the coefficient of friction to 0.003

• Factory preload adjustment prevents side-play and backlash

• Lightweight aluminum carriage and base with high load capacity

• Built-in holes simplify installation and component mounting

• Maintenance-free and available with varying precision grades and corrosion resistant materials

Del-Tron Precision offers linear slides in several levels of precision, ranging from a straight line accuracy of 0.0005” per inch of travel in our standard precision ball slides to 0.0000040” per inch of travel straight line accuracy in our high precision ball slides. Travels from ¼” to 12” are standard – and even longer travels are possible with our custom designs. Available with inch or metric holes and hole locations, these factory preloaded, low friction, light weight linear slides are ready for installation. For vertical applications involving higher speeds and cantilevered loads, Del-Tron Precision offers Anti-Creep linear slides. These units contain a one-piece ball retainer to maintain the position of the ball bearing retainer.

For compact, low-friction applications, Del-Tron offers precision linear ball slide bearings engineered for smooth, accurate travel.

Easily modified and customized to fit your requirements

While most users can find a linear slide that fits their application perfectly, right out of the box, when engineers need specific modifications for a particular application, Del-Tron Precision creates custom slides with special holes, slots, and travels to meet specific application requirements. Different component materials such as stainless steel can be utilized along with alternative coatings for cleanroom, and vacuum applications.

Three key linear slides applications

• The Semi-Conductor Industry: Clean running with few particulates, our linear slides function well in even the highest level of cleanrooms. Materials can be changed so that the slides perform well in practically any cleanroom environment.

• The Medical Equipment Industry: From mammography to digital imaging for medical applications to body fluid analysis, the medical industry depends on linear slides. For example, automated in-vitro diagnostic equipment, which analyzes body fluids, often utilizes miniature linear ball slides to perform up to 96 tests at one time. These slides are fitted with special components and coatings to withstand equipment wash-down procedures.

• Packaging and Assembly: Llinear slides play an important role in the assembly of cell phones, flat panel TVs, monitors and automotive components. They are also used in the packaging, testing and assembly of disposable medical equipment, defibrillators and pacemakers applications. In addition, they play a significant role in the production, testing and assembly of semiconductor chips, wafers and disc drives.

Interactive web site + calculators + technical support standing by

Del-Tron Precision's searchable database helps you zero in on the right linear motion product. It's as easy as simply plugging in your criteria and finding the one that best suits your specific application. Our load calculators and life calculators tell you whether a slide is a good choice for your application and how long it will last under your conditions.

For your convenience, all solid models for our entire product line are available for download. And if you have questions concerning your application, our staff engineers are standing by to discuss any modifications you require. You'll find our technical personnel are knowledgeable and highly responsive, enabling you to develop unique solutions with standard or customized linear slides. Always at the ready, you will receive the personalized attention you deserve, which is rare among high tech companies today. Del-Tron prides ourselves on an extremely high quality product line as well as excellent customer service.

For cost efficiency and quick turnaround times in quality, high-precision, miniature linear motion, Del-Tron Precision delivers. Visit www.Deltron.com or call 800-245-5013.

Click here for our Product Guide Catalog in Inches and for our Product Guide Catalog in Metric.