Custom Linear Motion Applications

Many custom linear motion applications require special design. Del-Tron Linear Engineering has the products, knowledge and expertise to help you design and achieve the perfect custom linear motion solution for your specific needs.

Based in the United States and with more than 40 years of experience, we have been providing our customers with design assistance, product prototyping and full service manufacturing for custom linear ball slides, custom crossed roller slides, custom positioning stages and complete linear positioning systems. Ranging anywhere from a standard ball or crossed roller slide requiring custom holes or special materials to a complex positioning system, Del-Tron Linear Engineering can help.

Our standard linear ball slides serve as the foundation for many custom assemblies, allowing engineers to adapt proven designs to unique requirements.

Utilizing our custom or standard linear slides, our knowledgeable engineers will provide you with immediate technical assistance, enabling you to find work-arounds to design and develop unique out-of-the-box solutions. You'll find we’re always ready to help and offer personalized attention that's unparalleled in the industry. We expect you'll experience a level of responsiveness you just won’t see anywhere else.

Help us to help you use our products!

Del-tron Precision has been offering custom linear motion solutions for many years. The examples below demonstrate only a few of our engineering capabilities to design custom linear motion solutions for specific applications. For additional information on how Del-Tron Linear Engineering can solve your custom linear motion needs, please contact us at 800-245-5013 or email us at deltron@deltron.com.

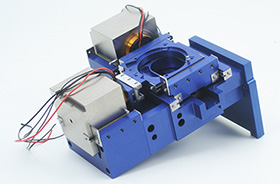

Custom Medical Application

This is an example of a Lasik eye surgery application where the end user required a precise XY positioning system capable of making high speed micro positioning adjustments. Precise repeatability and the unit's ability to hold position was a critical requirement. The customer was looking at Del-Tron's standard linear ball slides, but the complexity of assembling the high number of ball slides the application required made it unfeasible. Del-Tron's engineers were able to solve this problem by designing a series of custom ball slides that could be integrated into the assembly to greatly reduce linear friction. Six custom Del-Tron linear slides were incorporated into the design to provide the linear motion necessary. These linear ball slides were also designed with stainless steel internals and ceramic ball bearings to reduce the magnetism transferred by the voice coil motors to the system's work surface. This compact design helped our customer offer a cost effective alternative to Lasik procedures.

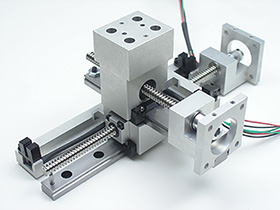

Custom Motorized Stage

A medical testing equipment manufacturer came to Del-Tron Linear Engineering for a custom motorized XY linear stage that could provide the overall accuracy, speed and reliability necessary for DNA testing. With space constraints being the major challenge, the footprint had travel, height, width and length restrictions. The custom stage also needed to be corrosion resistant. Del-Tron engineers started the design with low profile recirculating guide technology to provide the travel required in the space allotted. To minimize the stage's footprint, we also designed a combination one-piece motor flange and adjustable limit switch bracket that kept the stage well within its overall length and width requirements. This allowed the unit's travel to be adjusted when needed. All components were manufactured from stainless steel or anodized aluminum to provide corrosion resistance. The custom design of the carriage mounting brackets for both axes allowed the customer to mount their test plate to the Y plate at the required overall height.

Custom Manual Stage

Looking for an alternative to a competitor's manual positioning stage, another customer turned to Del-Tron to improve their design and provide cost savings. The customer requirements for the manual linear positioner included a 50mm travel in each axis and an overall height to match the existing stage. Their design incorporated externally mounted linear encoders. Our engineers responded to this request by designing a custom monolithic crossed roller XY positioning stage. The monolithic linear motion system, along with the crossed roller sets, was used to meet the height and accuracy requirements of the manual stage. Micrometers were used to provide the 50 mm travel in each axis of the manual linear positioners. Finally, the linear encoders were embedded internally in our design which eliminated the need for our customer to mount and align the linear encoders externally. This saved them both installation time and money while providing them with a manual linear positioner in a clean, elegant design solution.

Custom Positioning Stage

Another example of our custom linear motion system was a redesign of an antiquated, manually operated XY dovetail stage used in precision punch press equipment. The customer's goal to automate their punch press created a need for a custom motor controlled positioning system while maintaining the footprint of the existing XY stage. By designing a custom XY positioning stage and using crossed roller rails sets, Del-Tron engineers were able to create a high-load carrying custom XY stage that met their requirements. One of the design challenges was the need to create room for the stepper motors in the existing footprint. We accomplished this by mounting the bearing housings, lead screws and motor couplings internally to each axis while maintaining the travel requirements. An interchangeable top plate feature was also added to reduce their setup time to complete their custom linear motion system.

Del-Tron Precision has been creating unique linear motion systems since 1974. For additional information on how Del-Tron Linear Engineering can solve your custom linear motion needs, please contact us at 800-245-5013 or email us at deltron@deltron.com.

Click here for our Custom Linear Bearings Catalog.